Abstract

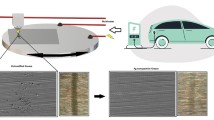

An experimental study of wear characteristics of electroless Ni–10% P coating sliding against hard AISI 52100 steel pin is investigated. Experiments are carried out at room and 550°C temperatures. Heat treatment effects on tribological behavior of this coating are studied. The wear surface and the microstructure of the coatings are analyzed using optical microscopy, scanning electron microscopy, energy dispersion analysis X-ray, and microhardness testing equipment. It is observed that the forming of continuous oxide film on contacting surfaces of pin and disk improves wear resistance and decreases friction coefficient of the Ni–10% P coating. The results indicate that the wear resistance of electroless Ni–10% P coating has improved with heat treatment at room temperature wear test, but it reverses in the wear test at 550°C. In addition, specimens without heat treatment have the highest wear resistance and the lowest friction for wear tests at elevated temperatures.

Similar content being viewed by others

References

Reidenbach F (1994) ASM handbook, surface engineering, vol 5. ASM International, Materials Park, pp 290–310

Stachowiak GW, Batchelor AW (2001) Engineering tribology. Butterworth Heinemann, Boston, p 614

Agarwala RC, Agarwala V (2003) Electroless alloy/composite coatings. Sadhana 28(3–4):475–93

Sahoo P, Das SK (2011) Tribology of electroless nickel coatings. Mater Des 32:1760–1775

Sahoo P (2009) Wear behavior of electroless Ni–P coatings and optimization of process parameters using Taguchi method. Mater Des 30:1341–1349

Sahoo P, Pal SK (2008) Tribological testing and optimisation of electroless Ni–P coatings based on Taguchi Method and grey relational analysis. Tribotest 14:127–144

Sahoo P, Pal SK (2007) Tribological performance optimization of electroless Ni–P coatings using the Taguchi method and grey relational analysis. Tribol Lett 28:191–201

Sahoo P (2008) Optimization of electroless Ni–P coatings based on multiple roughness characteristics. Surf Interface Anal 40:1552–1561

Balaraju JN, Rajam KS (2007) Electroless deposition and characterization of high phosphorus Ni–P–Si3N4 composite coatings. Int J Electrochem Sci 2:747–761

Elansezhian R, Ramamoorthy B, Nair PK (2008) Effect of surfactants on the mechanical properties of electroless (Ni–P) coating. Surf Coat Technol 203:709–712

Zhou QJ, Zhao JQ, Nie F, Chu WY, Li JX, Qiao LJ (2009) The effect of hydrogen on friction and wear of Ni–P electroless coating. Wear 266(7–8):810–813

Palaniappa M, Seshadri SK (2008) Friction and wear behavior of electroless Ni–P and Ni–W–P alloy coatings. Wear 265:735–740

Yan M, Ying HG, Ma TY (2008) Improved microhardness and wear resistance of the as-deposited electroless Ni–P coating. Surf Coat Technol 202:5909–5913

Ramalhoa A, Miranda JC (2005) Friction and wear of electroless NiP and NiP + PTFE coatings. Wear 259:828–834

Apachitei I, Tichelaar FD, Duszczyk J, Katgerman L (2002) The effect of heat treatment on the structure and abrasive wear resistance of autocatalytic NiP and NiP–SiC coatings. Surf Coat Technol 149(2–3):263–278

Ramalho A, Miranda JC (2007) Tribological characterization of electroless NiP coatings lubricated with biolubricants. Wear 263:592–597

Lin CJ, Chen KC, He JL (2006) The cavitation erosion behavior of electroless Ni–P–SiC composite coating. Wear 261:1390–1396

Wang L, Gao Y, Xu T, Xue Q (2006) Corrosion resistance and lubricated sliding wear behaviour of novel Ni–P graded alloys as an alternative to hard Cr deposits. Appl Surf Sci 252:7361–7372

Ashassi-Sorkhabi H, Rafizadeh SH (2004) Effect of coating time and heat treatment on structures and corrosion characteristics of electroless Ni–P alloy deposits. Surf Coat Technol 176(3):318–326

Keong KG, Sha W, Malinov S (2003) Hardness evolution of electroless nickel–phosphorus deposits with thermal processing. Surf Coat Technol 168:263–274

Taheri R, Oguocha INA, Yannacopoulos S (2001) Effect of heat treatment on age hardening behavior of electroless nickel–phosphorus coatings. Mater Sci Technol 17(3):278–284

Taheri R, Oguocha INA, Yannacopoulos S (2001) The tribological characteristics of electroless NiP coatings. Wear 249:389–396

Novak M, Vojtech D, Vitu T (2010) Influence of heat treatment on tribological properties of electroless Ni–P and Ni–P–Al2O3 coatings on 9Al–Si casting alloy. Appl Surf Sci 256:2956–2960

Alirezaei S, Monirvaghefi SM, Salehi M, Saatchi A (2007) Wear behavior of Ni–P and Ni–P–Al2O3 electroless coatings. Wear 262:978–985

Staia MH, Castillo EJ, Puchi ES, Lewis B, Hintermann HE (1996) Wear performance and mechanism of electroless Ni–P coating. Surf Coat Technol 86–87:598–602

Balaraju JN, Narayanan TSNS, Seshadri SK (2003) Electroless Ni–P composite coatings. J Appl Electrochem 33:807–816

Dong D, Chen XH, Xiao WT, Yang GB, Zhang PY (2009) Preparation and properties of electroless Ni–P–SiO2 composite coatings. Appl Surf Sci 255(15):7051–7055

Kashani H, Amadeh A, Ghasemi HM (2007) Room and high temperature wear behaviors of nickel and cobalt base weld overlay coatings on hot forging dies. Wear 262:800–806

Tsujikawa M, Azuma D, Hino M, Kimura H, Inoue A (2005) Friction and wear behavior of laser irradiated amorphous metal. J Meta stab Nanocryst Mater 24–25:375–378

Razavi RSh, Salehi M, Monirvaghefi M, Gordani GR (2008) Laser surface treatment of electroless Ni–P coatings on Al356 alloy. J Mater Process Technol 195:154–159

Pershin V, Lufitha M, Chandra S, Mostaghimi J (2003) Effect of substrate temperature on adhesion strength of plasma-sprayed nickel coatings. J Therm Spray Technol 12(3):370–376

Staia MH, Conzono A, Cruz MR, Roman A, Lesage J, Chicot D, Mesmacque G (2002) Wear Behavior of silicon carbide/electroless nickel composite coatings at high temperature. Surf Eng 18(4):265–269

Huang X, Wu Y, Qian L (2004) The tribological behavior of electroless Ni–P–SiC (nanometer particles) composite coatings. Plat Surf Finish 91:46–48

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Masoumi, F., Ghasemi, H.R., Ziaei, A.A. et al. Tribological characterization of electroless Ni–10% P coatings at elevated test temperature under dry conditions. Int J Adv Manuf Technol 62, 1063–1070 (2012). https://doi.org/10.1007/s00170-011-3832-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-011-3832-2